7" w.c. (17 mbar) Set Point Capacity Table (1" Droop)

Models N, R*

(capacities in SCFH of 0.6 S.G. gas; Base condition of 14.7 psia and 60°F)

Inlet

Pressure

(psig) |

ORIFICE SIZES |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

8" w.c. |

|

|

100 |

130 |

190 |

270 |

10" w.c. |

|

|

110 |

160 |

240 |

300 |

12" w.c. |

|

100 |

115 |

165 |

250 |

310 |

14" w.c. |

|

110 |

170 |

190 |

330 |

440 |

16" w.c. |

|

120 |

180 |

205 |

340 |

450 |

21" w.c. |

|

130 |

230 |

255 |

410 |

575 |

24" w.c. |

90 |

150 |

230 |

275 |

420 |

585 |

1 |

110 |

160 |

270 |

340 |

560 |

640 |

2 |

150 |

255 |

450 |

560 |

845 |

1120 |

3 |

190 |

325 |

560 |

770 |

1090 |

1470 |

5 |

260 |

470 |

830 |

1050 |

1400 |

1750 |

10 |

400 |

870 |

1470 |

1950 |

2200 |

2400 |

20 |

580 |

1020 |

1670 |

2120 |

2560 |

2650 |

30 |

700 |

1900 |

2550 |

2600 |

2680 |

2700 |

40 |

910 |

2300 |

2600 |

2630 |

2750 |

2760 |

50 |

1070 |

2370 |

2610 |

2670 |

2890 |

|

60 |

1150 |

2420 |

2700 |

2720 |

2930 |

|

70 |

1340 |

2500 |

2750 |

2770 |

|

|

80 |

1490 |

2510 |

2750 |

2790 |

|

|

90 |

1640 |

2510 |

2750 |

2790 |

|

|

100 |

1890 |

2520 |

2770 |

2790 |

|

|

125 |

2305 |

3420 |

2820 |

|

|

|

| |

| |

Do not operate orifice in shaded inlet pressure area |

| |

Inlet Pressure is too low to achieve desired outlet pressure |

Increased Pressure Above Set Point Required for No Flow |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.3" w.c. |

0.5" w.c. |

0.6" w.c. |

0.8" w.c. |

0.9" w.c. |

1.0" w.c. |

| |

Change in Outlet Pressure with a 10 psig Change in Inlet Pressure |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.1" w.c. |

0.2" w.c. |

0.3" w.c. |

0.3" w.c. |

0.4" w.c. |

0.5" w.c. |

TYPICAL PERFORMANCE CURVES

7" w.c. Set Point

Type and Model B-31 R

Regulator: Inlet Size 1-1/4" NPT

Outlet Size 1-1/4" NPT

Orifice Size 1/4" |

RELIEF CURVES - LEVER DISCONNECT

7" w.c. Set Point

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Vent Size 1" NPT |

14" w.c. (34 mbar) Set Point Capacity Table (2" Droop)

Models N, R*

(capacities in SCFH of 0.6 S.G. gas; Base condition of 14.7 psia and 60°F)

Inlet

Pressure

(psig) |

ORIFICE SIZES |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

16" w.c. |

|

90 |

130 |

170 |

185 |

260 |

21" w.c. |

70 |

110 |

150 |

190 |

205 |

305 |

24" w.c. |

80 |

120 |

160 |

225 |

225 |

340 |

1 |

100 |

145 |

200 |

240 |

290 |

410 |

2 |

120 |

210 |

300 |

380 |

475 |

630 |

3 |

155 |

270 |

375 |

500 |

580 |

820 |

5 |

210 |

380 |

560 |

660 |

800 |

1100 |

10 |

350 |

575 |

820 |

1000 |

118- |

1500 |

20 |

510 |

810 |

1240 |

1300 |

1700 |

1550 |

30 |

615 |

1100 |

1500 |

1450 |

1550 |

1400 |

40 |

790 |

1350 |

1740 |

1550 |

1400 |

1300 |

50 |

1000 |

1530 |

1820 |

1500 |

1450 |

|

60 |

1100 |

1950 |

1760 |

1400 |

1350 |

|

70 |

1300 |

2030 |

1650 |

1350 |

|

|

80 |

1350 |

2080 |

1600 |

1300 |

|

|

90 |

1450 |

`860 |

1530 |

1275 |

|

|

100 |

1520 |

2010 |

1580 |

|

|

|

| |

| |

Do not operate orifice in shaded inlet pressure area |

| |

Inlet Pressure is too low to achieve desired outlet pressure |

Increased Pressure Above Set Point Required for No Flow |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.4" w.c. |

0.6" w.c. |

0.7" w.c. |

0.9" w.c. |

0.9" w.c. |

0.9" w.c. |

| |

Change in Outlet Pressure with a 10 psig Change in Inlet Pressure |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.1" w.c. |

0.2" w.c. |

0.3" w.c. |

0.4" w.c. |

0.5" w.c. |

0.6" w.c. |

TYPICAL PERFORMANCE CURVES

14" w.c. Set Point

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Orifice Size 3/16" |

RELIEF CURVES - LEVER DISCONNECT

14" w.c. Set Point

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Vent Size 1" NPT |

1 psig (69 mbar) Set Point Capacity Table (1% Absolute Droop)

Models N, R*

(capacities in SCFH of 0.6 S.G. gas; Base condition of 14.7 psia and 60°F)

Inlet

Pressure

(psig) |

ORIFICE SIZES |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

2 |

120 |

200 |

230 |

310 |

360 |

480 |

3 |

160 |

250 |

330 |

420 |

480 |

640 |

5 |

190 |

360 |

490 |

580 |

670 |

880 |

8 |

230 |

480 |

670 |

780 |

890 |

1260 |

10 |

310 |

550 |

730 |

900 |

1050 |

1370 |

15 |

410 |

690 |

980 |

1170 |

1350 |

1810 |

20 |

500 |

830 |

1150 |

1400 |

1600 |

2100 |

30 |

640 |

1120 |

1520 |

1760 |

2060 |

2150 |

40 |

780 |

1560 |

1920 |

2160 |

2280 |

2300 |

50 |

950 |

1610 |

2170 |

2360 |

2380 |

|

60 |

1100 |

1800 |

2360 |

2530 |

2550 |

|

75 |

1340 |

1960 |

2500 |

2680 |

|

|

85 |

1510 |

2550 |

2850 |

2810 |

|

|

100 |

1760 |

2870 |

3010 |

3100 |

|

|

| |

| |

Do not operate orifice in shaded inlet pressure area |

Increased Pressure Above Set Point Required for No Flow |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.04 psi |

0.04 psi |

0.04 psi |

0.06 psi |

0.06 psi |

0.06 psi |

| |

Change in Outlet Pressure with a 10 psig Change in Inlet Pressure |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.01 psig |

0.02 psig |

0.02 psig |

0.03 psig |

0.03 psig |

0.04 psig |

1 psig (69 mbar) Set Point Capacity Table (2% Absolute Droop)

Inlet

Pressure

(psig) |

ORIFICE SIZES |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

2 |

150 |

300 |

420 |

550 |

660 |

880 |

3 |

200 |

370 |

550 |

730 |

860 |

1190 |

5 |

250 |

540 |

770 |

990 |

1220 |

1630 |

8 |

330 |

700 |

1030 |

1360 |

1640 |

2200 |

10 |

370 |

800 |

1200 |

1560 |

1900 |

2410 |

15 |

470 |

1030 |

1600 |

2020 |

2380 |

3100 |

20 |

550 |

1250 |

1900 |

2420 |

2920 |

2400 |

30 |

700 |

1610 |

2490 |

3080 |

3300 |

3400 |

40 |

860 |

1980 |

3100 |

3420 |

4140 |

4200 |

50 |

1010 |

2300 |

3500 |

3640 |

4300 |

|

60 |

1170 |

2680 |

3680 |

3940 |

4350 |

|

75 |

1400 |

2940 |

3290 |

4220 |

|

|

85 |

1600 |

3480 |

4250 |

4500 |

|

|

100 |

1820 |

3930 |

4600 |

4600 |

|

|

| |

| |

Do not operate orifice in shaded inlet pressure area |

TYPICAL PERFORMANCE CURVES

1 PSIG SET POINT

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Orifice Size 3/16" |

RELIEF CURVES - LEVER DISCONNECT

1 PSIG Set Point

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Vent Size 1" NPT |

2 psig (138 mbar) Set Point Capacity Table (1% Absolute Droop)

Models N, R*

(capacities in SCFH of 0.6 S.G. gas; Base condition of 14.7 psia and 60°F)

Inlet

Pressure

(psig) |

ORIFICE SIZES |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

3 |

100 |

120 |

190 |

210 |

230 |

280 |

5 |

140 |

160 |

260 |

320 |

350 |

450 |

10 |

250 |

290 |

500 |

550 |

600 |

700 |

20 |

450 |

500 |

800 |

900 |

1000 |

1200 |

30 |

550 |

600 |

1000 |

1200 |

1200 |

1400 |

40 |

650 |

800 |

1200 |

1300 |

1500 |

1600 |

50 |

800 |

900 |

1400 |

1600 |

1700 |

|

60 |

900 |

1100 |

1500 |

1700 |

1700 |

|

70 |

955 |

1150 |

1600 |

1700 |

|

|

80 |

1100 |

1250 |

1700 |

1700 |

|

|

90 |

1250 |

1320 |

1700 |

1700 |

|

|

100 |

1400 |

1400 |

1700 |

1700 |

|

|

125 |

1600 |

1700 |

1700 |

|

|

|

| |

| |

Do not operate orifice in shaded inlet pressure area |

Increased Pressure Above Set Point Required for No Flow |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.04 psi |

0.05 psi |

0.05 psi |

0.06 psi |

0.06 psi |

0.06 psi |

| |

Change in Outlet Pressure with a 10 psig Change in Inlet Pressure |

Orifice |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

Pressure |

0.01 psig |

0.02 psig |

0.03 psig |

0.04 psig |

0.05 psig |

0.06 psig |

2 psig (138 mbar) Set Point Capacity Table (2% Absolute Droop)

Inlet

Pressure

(psig) |

ORIFICE SIZES |

1/8" |

3/16" |

1/4" |

5/16" |

3/8" |

1/2" |

3 |

120 |

200 |

320 |

400 |

480 |

530 |

5 |

190 |

330 |

500 |

600 |

700 |

850 |

10 |

280 |

550 |

800 |

1000 |

1100 |

1320 |

20 |

550 |

900 |

1300 |

1500 |

1800 |

2000 |

30 |

700 |

1100 |

1700 |

2000 |

2100 |

2300 |

40 |

800 |

1400 |

2000 |

2300 |

2300 |

2700 |

50 |

1100 |

1700 |

2400 |

2500 |

2500 |

|

60 |

1100 |

2000 |

2500 |

2620 |

2700 |

|

70 |

1125 |

2100 |

2600 |

2850 |

|

|

80 |

1300 |

2150 |

2800 |

2940 |

|

|

90 |

1475 |

2250 |

2800 |

3000 |

|

|

100 |

1700 |

2250 |

2810 |

3060 |

|

|

125 |

2100 |

2420 |

2980 |

|

|

|

| |

| |

Do not operate orifice in shaded inlet pressure area |

TYPICAL PERFORMANCE CURVES

2 PSIG SET POINT

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Orifice Size 3/16" |

RELIEF CURVES - LEVER DISCONNECT

2 PSIG Set Point

Type and Model B-31 R

Regulator: Inlet Size 3/4" NPT

Outlet Size 1" NPT

Vent Size 1" NPT |

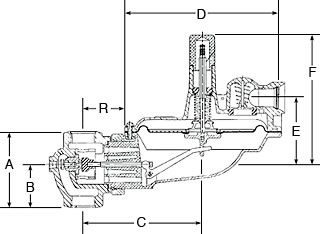

See the PDF for more information on Model B31IMR, B31IMRV, and B31IMN,

Internal Monitor(IM) Principle of Operation

![]()

Appropriate for light

commercial and industrial

uses where inches of water

column or pounds delivery is

desired such as utility

services, and small to medium

sized furnaces and boilers.

The rapid response of the B31

is particularly well suited for

applications where sudden

on/off loads could cause

shock problems.

Appropriate for light

commercial and industrial

uses where inches of water

column or pounds delivery is

desired such as utility

services, and small to medium

sized furnaces and boilers.

The rapid response of the B31

is particularly well suited for

applications where sudden

on/off loads could cause

shock problems.