ISTEC CORPORATION

Flow Measurement & Control

5 Park Lake Road, Unit 6

Sparta, NJ 07871 USA

Tel 973-383-9888

Fax 973-383-9088

Email

Newsletter Sign-up Here

OFFICE HOURS

We will be closed on May 24th and May 27th, 2019 in observation of Memorial Day.

We will open again on Tuesday May 28th, 2019

Remember our troops in your prayers as they keep us safe on this Memorial Day.

We Accept

![]()

Last Update:

Model “A” Series Gas Meters

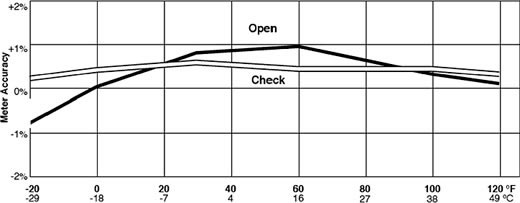

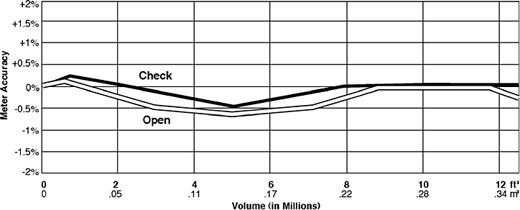

The "A" Series commercial diaphragm meters comprise a range of positive displacement gas measurement devices with capacities of 400 to 1000 ft3/hr (11m3/hr to28m3/hr). These meters use proven diaphragm meter technology in a 3-chambered design to provide accurate measurement across their respective flow ranges. Long-life and low maintenance are assured by the combination of a self-lapping orbital valve, a one-piece seamless diaphragm, and few moving parts. Careful attention to design makes them compact and lightweight for their capacity ratings.

The "A" Series commercial diaphragm meters comprise a range of positive displacement gas measurement devices with capacities of 400 to 1000 ft3/hr (11m3/hr to28m3/hr). These meters use proven diaphragm meter technology in a 3-chambered design to provide accurate measurement across their respective flow ranges. Long-life and low maintenance are assured by the combination of a self-lapping orbital valve, a one-piece seamless diaphragm, and few moving parts. Careful attention to design makes them compact and lightweight for their capacity ratings.

COMPATIBILITY

These meters are intended primarily for use with natural gas, but are compatible with a variety of non-corrosive dry gases. A compatibility listing is found in the table at right. For gases not listed, contact ISTEC Corporation.