ISTEC CORPORATION

Flow Measurement & Control

5 Park Lake Road, Unit 6

Sparta, NJ 07871 USA

Tel 973-383-9888

Fax 973-383-9088

Email

Newsletter Sign-up Here

OFFICE HOURS

We will be closed on May 24th and May 27th, 2019 in observation of Memorial Day.

We will open again on Tuesday May 28th, 2019

Remember our troops in your prayers as they keep us safe on this Memorial Day.

We Accept

![]()

Last Update:

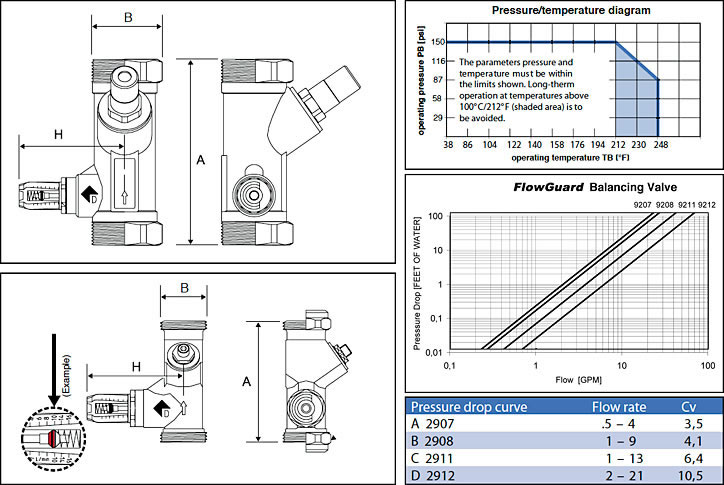

2900 Series FlowGuard™ Balancing Valve

ISTEC FlowGuard™ Balancing Valves are ideal for Heating, Ventilation, Air-conditioning, as well as Solar and Heat Pump Systems.

ISTEC FlowGuard™ Balancing Valves are ideal for Heating, Ventilation, Air-conditioning, as well as Solar and Heat Pump Systems.

Accurate flow balancing with the multi-turn inclined seat valve

- Continuous Indication of the Actual Flow Rate

- No Need for Measuring Computers or Charts

- MemoStop Function for Presetting and Locking Flow Rate

- Works in Any Position

- No Correction Charts Required for Glycol Additives